- Initial Depth: 9.8 metres

- Final depth: 17 metres

- Working sessions: 137

- Kibble loads out: 458

- Concrete mixer loads: 71

Clive North, Jeff Price, Stuart Lindsay, Tim Large, Tony Audsley

Kibbles: 6

We had a rather late start (1130) and I think that we all felt rather slow and heavy for some reason. Eventually, we got started and spent the rest of the morning in a deep and meaningful dialogue with the rock walls at the bottom of the drop ...

... In the afternoon, Jeff and Stuart went down to muck out the debris and they sent up six kibbles of spoil. There was little else of note except that Tim had a disagreement with my petrol stove and created a spectacular fireball about one metre in diameter. This set fire to the safety notice attached to the petrol pipe of the stove, completely blackened the kettle and filled the shelter with floating soots. Petrol stoves have real entertainment value, better than these mamby-pamby gas abominations, which just sit there and hiss.

Alice Audsley, Annie Audsley, Jeff Price, Mike Wilson, Roger Galloway, Stuart Lindsay, Tony Audsley

Digga the dog

Kibbles: 12

First thing, Annie and Roger went down the shaft and produced a line survey of the dig. Then Annie, Roger and Mike ran a 70mm (ish) I.D flexible pipe from the surface to the end of the dig and Tony fixed a VERY old Hoover "Dustette" vacuum cleaner at the surface end of the pipe. All junctions made sound and secure using short lengths of rainwater downpipe inserted inside the pipes and a liberal plastering of gaffer tape on the outside.

This done, we softened up the constriction at the bottom of the drop, turned on the ventilation system and sat round the shaft drinking hot Gluhwein for half an hour or so.

Annie, Jeff, Roger and Stuart then went underground and sent up 12 Kibbles of muck, lowering the floor by some 3 ft, (or a metre if you prefer that sort of thing). Unfortunately, the way on down is still closed by broken rock and the walls of the drop need more enlargement before we can dig it out effectively. However, the good news is that my Sunday-Best crow bar, last seen on 23rd November has been recovered.

Alice Audsley, Mike Wilson, Stuart Lindsay, Tim Large, Tony Audsley

We started at the Belfry where Stuart, Tim and I loaded sheets of wriggly tin into the van. We then drove in convoy to the dairy unit at Wigmore where we spent some time discussing the best way to get the wriggly tin and other bulky items over to the dig. We thought that the field was still sufficiently frozen to allow Tim to drive to the dig towing the wriggly tin sheets behind his truck. This was not entirely a good idea. It got the heavy items over to the dig, but it did plough up the field rather badly and we had been trying to avoid this.

Over at the dig, we met up with Mike and later Alice, who arrived with an emergency supply of screws. Mike got up on the roof of the new shelter and laid down two layers of heavy duty polythene sheeting. He then fixed the sheets of tin on top.

Stuart had found a couple of sheets of perspex, so he cut a slot in the west wall and fitted on the perspex as a window. This done, we installed a table in the shelter and immediately set up the stove on top and started boiling the kettle for some tea. Meanwhile Stuart cut another slot in the south wall for a second window.

Jeff Price, Stuart Lindsay, Tim Large, Tony Audsley

The original plan for today had been to start work on the winter digging shelter and then later to do a bit of rock removal at the end of RDR. However, things didn't go quite according to plan.

First thing, Jeff and I fitted a new fuel tap to Stuart's generator to replace the one that had suddenly sheared off. This done we had power for the circular saw.

With this out of the way we started work on building the shelter against the south wall of the digging hut / engine house. It was a rather rough and ready construction with 8 × 4 sheets of ply bolted and screwed to 90 mm square timber uprights at the corners. Tim did most of the fixing and the rest of us did most of the holding, which is the difficult part.

As the work progressed, the weather deteriorated and the wind increased. We realised that the structure would need to be complete, roof and all before it would be safe to leave it. So we abandoned the idea of working underground, which was probably just as well as during the afternoon, the skies opened in an incredible downpour, the depression quickly became flooded and an impressive roar of falling water could be heard at the top of the shaft.

At some stage during the late afternoon, I fell off the foundation wall for the new shelter and landed in an untidy heap on the water and rocks below. For me, this made the remainder of the day seem a bit more unpleasant than it actually was.

Eventually we fitted the roof sheets which made the structure secure enough to leave it for the time being, so we packed up and walked back across the sodden field.

Footnote, Mon 12th

I spent a happy 4½ hours in the A & E department of Weston Hospital being X-Rayed for suspected fractured patella [thank goodness it wasn't], then being stitched up - great fun. But I won't be climbing the ladder in the shaft for a bit.

Alice Audsley, Ian Gregory (Slug), Jeff Price, Mike Wilson, Stuart Lindsay, Tony Audsley

Vince Simmonds (visited in the afternoon)

Kibbles: 10

A day of horrible weather and rather slow progress. Jeff and Stuart went down first and started clearing the rubble out of the drop, Jeff in the hole passing the stuff back to Stuart who bagged it. I followed them down a little later, then Jeff and I took turns in working in the drop.

We concentrated on chiselling the cracked up rock off the walls of the drop to enlarge it sufficiently to allow us to squat down and reach the material on the floor. This was slow work and rather tedious, but at least we had a better time of it than the team on the surface who were battered with strong cold winds and intermittent heavy showers of rain while dealing with the spoil.

In the afternoon Stuart had a few capping sessions to try to cut into the walls. He had somewhat mixed success with this as clay partings within the rock made it difficult to set the caps off.

By the end of the day, we had managed to produce a narrow shaft, almost 2 metres deep, still solidly choked at the bottom. We did, however, uncover a narrow slot (about 7cm wide) off to the side, which trends back under RD Rift and there is a slight hint of a cold draught.

Alice Audsley, Clive North, Dudley Herbert, Mike Wilson, Stuart Lindsay, Tim Large, Tony Audsley

Kibbles: 17

Stuart and I went and started work on clearing and enlarging the top of the drop. We had managed to block this entirely with rubble and it was great fun to clear it working head down and passing the stuff back to Stuart. After clearing most of the fines, I started lifting out the large blocks. Unfortunately as I was pulling on a key stone, it slipped from my hand and precipitated a collapse of most of the remaining debris down into the rift below. The way on is blocked AGAIN.

In the afternoon, Stuart and I cleared the stacked bags from Wed 23rd and today's spoil totalling 17 kibbles in total, largely broken rock. Stuart then started capping bits off the left wall of RD Rift to improve access and I dismantled the traverse abomination and sent it to the surface.

Alice Audsley, Jeff Price, Tony Audsley

All three underground, clearing the remains of the rock that had overhung the drop. We bagged the broken rock and stacked the bags at the base of the shaft ready for Sunday's session.

The shaft/rift/way-on needs more widening before we can get down it. The best estimate puts it something in the region of 200 millibatstones.

Jeff did try knocking some of the nodules off the wall with my Sunday Best crow-bar but only succeeded in dropping it down the hole. I guess he owes me some beer for that.

P.S. There was a log entry number 129, but it was only about surface house-keeping and the like and was altogether too boring to inflict on anyone.

Alice Audsley, Chris Batstone, Ross Davidson (GSG), Stuart Lindsay, Tim Large, Tony Audsley

Roger Marsh (visited in the afternoon}

Kibbles: 9

The weekend of the JRat digging award combined with the celebration of the 75th anniversary of the Mendip Rescue Organization.

This year the digging award was won by a Scottish team for their work at a cave near Applecross, Ross-shire known variously as Flood Resurgence No 2, FRN2, or now more properly as Uamh Nam Fior Iongantais (the cave of true wonders).

A small contingent of the GSG had travelled south to attend the award and we had managed to inveigle one of them, Ross Davidson into spending a day at the dig. Stuart, Ross and I met up at the Belfry and loaded some 8 × 4 sheets of ply into Stuart's van. More material for building our winter shelter.

At the dig, we were joined by the rest of the team and Ross and I went down and installed the wire traverse. This done, we were joined by Stuart; then Ross and Stuart started digging at the rear of the chamber while I started drilling into the obstructive rock at the head of the drop with the intention of eventually removing it.

It very soon emerged that the traverse system was A.F.U. (a technical term indicating that it didn't work very well) and it was abandoned in favour of passing the bags of spoil by hand. Nine kibbles of semi-liquid goo were sent to the surface where they were fielded by Chris on the winch, Alice on the bank and Tim as barrow-man.

The day's digging ended with the team sitting round a gently smoking shaft while drinking tea and eating stollen cake.

Tony Audsley

Digging from home! Making up a traverse wire and Blondin to move bags of spoil from the back of the chamber up to the base of the shaft. This is just a temporary measure, but it is likely to be less fraught than manhandling the kibble in and out of the chamber using the power winch. Tried that once, didn't like it. The traverse head was made up from two lengths of 40 × 2 mm strip encasing two 50mm diameter cast iron pulley wheels. These are smaller than I would have wished but that's what was available.

My thanks to Dave Speed for his help with this.

Alice Audsley, Mike Wilson, Stuart Lindsay, Tim Large, Tony Audsley

Kibbles: 5

Tim and I went underground, where most of the morning was taken up by inserting a pair of metal grids, which happened to be more or less the correct size to act as shoring to retain the semi-mobile slope of fill in the chamber. There is a steeply sloping rock floor on either side of the chamber, but in the centre there is a metre(ish) wide trench which seems to be an open continuation of RD Rift. This trench is filled with fluid clay and small rubble which is trying to sludge its way down into the rift and undermine the base of the shaft at the same time.

The grids were stacked in place against the by now almost vertical slope of fill and held in place by eight 12 mm re-bar pins drilled into the rock walls of the trench. Four bits of psychological timber battening and a few wooden wedges were added and the whole topped off with a light sprinkling of cable ties. Unashamed bodgery, but it will do for the time being until we see how the area develops.

Meanwhile, Tim attacked the offending rock at the top of the drop in RD Rift. The result of much hammering, chiselling and levering was an exhausted Tim and a smugly unmoved block; you could almost see the smirk on its face.

Lunch was enhanced by a blackcurrent and apple pie, brought by Stuart.

In the afternoon, Tim and I descended once again into the mire and tried digging below the shoring by disconnecting the kibble from its guide cable and handling it down into the chamber. This, and in particular the return journey, was a slow and rather fraught process and not to be repeated without further thought and considerable modification. Despite this, we managed to send up five kibbles of mixed rock and sludge.

On the surface, Stuart continued building drystone spoil retaining walls in strange places, all the time grumbling bitterly about the lack of spoil and the slow rate of the digging.

Tea-time and Tim produced a Stollen cake. After tea, we dried off, cleared up and finished as dusk was falling.

An Aside: During the excavation of the fill in the trench, a curious rounded cobble turned up, which appears to be sandstone. The upper surface of the cobble is rounded, but the lower surface is almost perfectly flat (to within about 1mm); strictly speaking it is very slightly concave in the centre. It is very similar in shape to a tea-cake or bap. Further investigation is required.

Clive North, Tim Large, Tony Audsley

Tim and I went underground and attacked the loose rock on the walls of RD Rift from each end, Tim from the inside and me from the outside. After we had removed as much as possible, we started lowering the floor, excavating clay which graded into small stones as we got deeper. There were voids running down through the stony layer and on opening these, Tim was certain he detected a 'farmyard smell'. If he is right then that implies an open connection to the Wigmore streamway some 100 metres below.

One photograph shows Tim working in the rift at the start of the session. The second photograph shows the rift after we had cleared the loose material from the walls and lowered the floor somewhat.

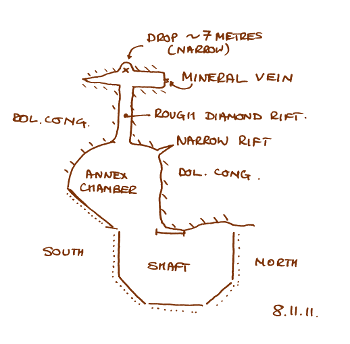

I include the diagram above in the hope that it will make all this verbiage a little clearer. While it may be topologically correct, it should in no way be considered as a sketch survey, more an arrangement drawing. To give an idea of size, the shaft is roughly one metre between opposite faces (segments), from the east face of the shaft to the start of RDR is 3.3 metres and from the start of RDR to the drop in the cross rift a further 3 metres. The drop was plumbed at 3.5 ish metres (so much for our previous estimates), although to be fair, we couldn't get the tape right to the bottom of the hole.

Alice Audsley, Mike Wilson, Stuart Lindsay, Tim Large, Tony Audsley

Kibbles: 38

I went down to inspect the results of last week's efforts and to take some photographs. The floor at the rear of the chamber had been lowered considerably and solid rock had been exposed in the floor on the right. This could be the bottom of a bedding plane running under the rear wall of the chamber. There is a gap between this and the solid previously exposed on the left, filled with wet clay and Harptree Beds rubble. This needs shoring.

At the junction of RD Rift and the cross rift, the area had been cleared and it is now possible to squint down the drop there. This appears to be in the region of 7 metres deep, but it is difficult to be precise as it is narrow and twisted. Nevertheless, it does look like a good candidate for the 'way on', but there will have to be a lot of heated discussions with the surrounding rock before we can get down it.

Stuart then came down and started digging at the rear of the Annex chamber, while I acted as kibble filling monitor.

After lunch, Stuart and Tim went down and continued the excavation at the rear of the chamber. This is now very squalid because of the heavy drip in the chamber but voids are opening in the floor and this should allow some drainage during the week.

Alice Audsley, Annie Audsley, John Crae, Mark Brown, Norman Flux, Preston White, Roger Galloway, Tony Audsley

Alice and I had a bit of a diversion to the far north to attend the Grampian Speleological Group's annual dinner and we then did a tiny bit of digging with the GSG on their home territory. I mention it here because of the interesting winch used at the dig. This is a product of the devious and cunning mind of Norman Flux. The winch works on a counterbalance principle. It has two drums which, (like the breasts of the young girl from Devizes †), are of two different sizes. In one neat stroke this balances both the differences in weight and distances travelled of the bucket and the human counterbalance. In use, the bucket is filled, a caver climbs to the top of the ladder, clips on and then slides gracefully down the ladder. The caver goes down and the bucket comes up. Simple.

-------

(†)There was a young girl from Devizes

Who had breasts of two different sizes

One was so small, it was no size at all,

But the other was HUGE and won prizes.

Chris Batstone, Duncan Butler, Jeff Price, Mike Wilson, Stuart Lindsay, Tim Large

Kibbles: 42

NOTE: What follows is compiled from Tim & Stuart's reports.

Stuart went down first and started clearing, then he was joined by Duncan. The intention was to get Duncan beyond the squeeze, but this was still blocked with broken rock so they spent about 2½ hours clearing the approach while Tim worked at the bottom of the shaft transferring loads to the kibble to be dealt with by Chris, Mike and Jeff on the surface.

At the start of the afternoon shift, Duncan managed to get to the other side of the squeeze. He was fed a hammer, chisel and a supply of bags and left to get on with it. Meanwhile, Stuart and Tim worked on clearing more fill from the approach passage and the base of the shaft.

The air quality was variable. At the end of the morning session, with three people working at the bottom, the chamber and rift were filled with condensation haze, but during the mid-day break this cleared, so perhaps the draught is still with us, although it is not very obvious.

The way on is down in the floor at the junction with the cross rift, where the fill has slumped. This is too tight to get into at the moment and choked with boulders, but with black inviting spaces in between.

Alice Audsley, Jeff Price, Mike Wilson, Stuart Lindsay, Tim Large, Tony Audsley

Kibbles: 6

Mixer Loads: 6

Alice, Stuart and I were first to arrive, and I went down to take a couple of quick photographs of the rift before work started in earnest. The photograph shows the rift and the top of the way on as the more or less circular darker patch rear centre right (marked 'X' on the enlarged image). Having got that out of the way, Stuart and I then sat in the Annex chamber and discussed the various options for today. We came to the conclusion that it would be sensible, if not a little boring, to complete the concreting of the shaft (south-east segment No. 6D) and concrete another section of the left-hand wall of the Annex chamber, which was about to slump if given half a chance. It had THAT look about it.

I came up the shaft, and found that Mike had arrived, so he took over the winch, Alice worked the bank and I barrowed and tipped. Five loads of previously filled bags were cleared out of the chamber and sent to the surface. One more load came out from behind the shuttering line of segment 6D in the shaft. Then followed a period of measuring, sawing, hacking and scratching of heads to produce shuttering for the new section of concrete in the Annex. Having got something more or less the right shape, we called a halt, Alice set up the BBQ, the depression filled with smoke and we had sausages, burgers, crisps and the like. More filling than our usual mid-day fare.

After the BBQ, Jeff and I went down, drilled holes into whatever solid was available then tangled together some 12mm re-bar, cut and bent to shape by the surface team. Viewed from below, bundles of re-bar being lowered down a concrete shaft can be both musical and worrying, a sort of cross between wind-chimes and swords of Damocles. It didn't pay to look too closely at the knots used to tie the bundles.

The shuttering was set up about a hand's width proud of the line of the previous two sections. This allowed the void to be filled easily and it will form a shelf when it has set on which can be placed small china ornaments, mugs of tea and such like. The shuttering itself was made from a couple of pieces of ply (and the inevitable polystyrene).

I have this theory that the various bits of shuttering will be held together firmly by the pressure of the concrete; so far, this has proved to be the case. The shuttering was held in place on the right by 10mm re-bar pins drilled into the rock and on the left by not very much but it didn't move. When the shuttering was full to the top, we added a psychological Acrow prop braced against the opposite wall, 'cos it looked good, but apart from possibly giving the impression that we knew what we about, it didn't add much in the way of support. Best part of all this was consuming a mug of tea and a HUGE slice of sticky toffee cake (courtesy of Tim), which Jeff had carried down the shaft.

The section under the Annex wall took four mixer loads to complete and we were getting short of concrete, so Mike drove off to get another bag. Meanwhile, I started on filling the last shaft segment of the fourth shaft ring (ring D). This took a further two loads, except for one kibble's worth. This remaining amount was bagged into three sausages and I stuffed these above the sleepers in the roof of the Annex to support the boulders above. There was a rip in the last bag and quite a lot of the contents went down the neck of my oversuit as the bag was being pushed into the hole, but some of it stayed up there. (Note: It's quite difficult to get concrete out of Velcro and a nylon zip once it has set.)

We packed up and had finished just after 6pm. A long and completely exhausting day for all concerned, but very enjoyable.

Afterthought - forgot to mention this earlier. We have decided to define an accessibility index to apply to any passages found at Home Close. The new SI unit of accessibility is to be 'The Batstone'. Thus RD Rift was originally something like a 300 millibatstone passage, possibly even less. After a bit of work it is now approaching 500 to 600 millibatstones, so there is some more work to do here. We are hoping that the unit will be adopted generally for the description of cave passages. It has much to recommend it. (Apologies to Chris).

Clive North, Jeff Price, Tim Large, Tony Audsley

Kibbles: 9

A slightly short session, 1030-1600. Tim and I went underground and started lowering the floor at the back of the Annex chamber, exposing more of the bedding plane at the back of the chamber and also the block of rock in the floor. Material from this excavation was stacked round the chamber if in bags or at the bottom of the shaft if rock. It soon got to the stage that there was no space left to stack. Some would have to be sent up to the surface.

I went up, started the winch and had hauled up 4 kibbles when Jeff turned up. Jeff went down to look at the bottom then he and Tim sent up another 5 kibbles, largely of rock, Mudstone and Harptree Beds. At this point (1330) it was lunch-time so Jeff and Tim came up.

After lunch Clive came over and drank tea while I went down and spent some time enlarging the tight section at the end of the rift. I emerged from the rift puffing and blowing like a leaky old steam engine, much to the amusement of the others.

Alice Audsley, Stuart Lindsay, Tony Audsley

Simon Meade-King

An afternoon session 1430-1745. Stuart went down and excavated in the Annex chamber, bagging spoil then stacking the bags under the concreted left-hand wall to prevent collapse. The back wall appears to undercut and further excavation revealed a large block in the floor. This appears to be dolomitic conglomerate and may well be bedrock as it rings very nicely when struck.

At the same time, I worked at the bottom of the shaft, managed to remove the stuck side cheek from the east segment (7D) and then installed the shuttering for the south-east segment 6D. I then dug out the floor of the bottom of the shaft, bagged to spoil and dropped the bags on top of Stuart in the Annex.

On the surface, Alice periodically dropped digging bags down the shaft when requested; often onto our heads; that bit wasn't requested.

We came out after about two hours underground and then spent some time on the surface talking to Simon, who had come over on a tour of inspection. We noticed with a certain amount of disapproval that Simon did not bring any cake.

Chris Batstone, Stuart Lindsay, Tim Large, Tony Audsley

Kibbles: 11

Mixer Loads: 2

The plan had been to concrete the two remaining segments of level D in the shaft. These were numbers 8 and 6 on the north-east and south-east of the shaft. However, events ruled the day and we did not manage to do this, also curiosity got the better of us.

The session started with Stuart going below and lowering the floor of the Annex to improved access to RD Rift in preparation for another dose of concrete support for the left-hand wall of the Annex. Meanwhile, on the surface, Tim moved the timber heap from the west of the site leaving that area free for the new, huge spoil heap that is likely to appear soon.

Chris turned up with heaps of jam donuts for all. After these had vanished and the inevitable tea drunk, I went down and started removing the shuttering from seg 7 (east) with the intention of setting up shuttering for 8 and 6 on either side of this. This is where the course of the day changed. The right-hand side cheek was firmly jammed in position and it was not going to be possible to get it out in time to finish the planned work today. So, we concentrated on the north-east segment and left the other for another day.

Meanwhile, Tim had another go at RDR. At the expense of a considerably bruised sternum, he passed the constriction about 8ft (2.4m) into RDR and ended up in a cross rift about 12ft (4ish metres) from the entrance. Here he was able stand up, but all other movement was impossible. The way on appeared to be down in the floor. He was pretty well stuck in there so I fed him hammer and chisels and left him to chip his way out while I continued working on the shuttering. The whole of this extension is small and both it and the RDR approach will need enlarging before it can be dug effectively. But it is likely to be the best way on and there IS a (slight) draught.

Eventually, Tim managed to dig his way out, then went on up (grinning horribly). Then the usual round of concreting started. Chris, Stuart and Tim mixed and lowered and I trowelled and tamped. One and two thirds mixer loads went into the segment, leaving one cement kibble unused. Stuart had the idea of bagging this into five small sausage bags and I inserted these into the void above and to the left (south) of the sleeper supports in the roof of the Annex in an attempt to support the crumbling spoil behind. (The photograph shows the concreting kibble and the just completed segment 8 to the left).

SO, we only did half the concreting we intended, BUT we doubled our length of open passage AND we had chocolate cake for tea! Can't grumble at that.

Jeff Price, Rich Witcombe, Tim Large, Tony Audsley

Mixer Loads: 2

Tim started by modifying his tarpaulin support framework on the north side of the shaft. He ran two horizontal scaff bars out from the headframe and supported them with two verticals. The shaft gate now clears this framework. Tim refitted the tarpaulin.

Meanwhile, Tony went below and dismantled the ply shuttering in the Annex. This revealed that the concrete had not been well tamped and it did rather resemble Russian mass concrete. The metal shuttering was then removed from the adjacent segment 5D, which had been cast at the same time. This also was not the best we have ever done.

The shuttering for 7D (east level 4) was then set up. A small amount of clearing was necessary before the side cheeks could be fitted. Tony then came up to find that Jeff had arrived some time before and that it was time for lunch.

Afterwards, Rich arrived, in answer to my earlier telephoned plea for help. (It really needs three on the surface to do all the carrying and mixing). The three of them then went underground to inspect RD Rift. Tim forced his way in again and is convinced:-

- That there is a drop at the end of the passage. Stones can be kicked over and judging by the sound, appear to fall some 10 ft(3m).

- That there is a slight but definite outwards DRAUGHT.

That was enough excitement for one day, so Jeff, Rich and Tim came back to the surface to start up the mixer and I (Tony) went down and fitted the re-bar, then made myself comfortable on a pile of digging bags in preparation for an afternoon's concreting. Two loads were used altogether. The first mix was a trifle too sloppy - Tim said that the water they used had been too wet, so that probably explains it.

We finished, cleaned and packed up by about 1630.

Chris Batstone, Mike Wilson, Stuart Lindsay, Tim Large, Clive North, Tony Audsley

Kibbles: 21

NOTE: Today was the 34th BEC Vintagers' Annual Luncheon held at Coxley Vineyard, 12 noon onwards. So while I feasted, the rest of the team got on with some hard digging unhindered by my usual delaying tactics. I left the celebrations rather early at 1600 hrs, getting to the dig at 1700.

The team had enjoyed a fantastic digging session, Stuart and Tim underground sending up 21 kibbles of spoil to Chris and Mike on the surface. Some of the spoil had come from under shaft segment 7C (east), in preparation for concreting 7D below, bringing it to the same level as 1D (north) and 5D (south). This will leave 6D (south-west) and 8D (north-west) still to do to complete the fourth section of concrete.

Their major effort, however, was within the Annex chamber, where the floor was lowered towards the rear (west) of the chamber, sloping down steeply from the entrance and the base of the concreted left-hand wall. Stuart and Tim uncovered much more of the left hand rift and Tim was able to worm his way feet-first into this for almost two body lengths. The rift continues but it needs further clearing and, ideally, the floor of the Annex chamber needs lowering some more to improve access.

Tim suggested the name 'Rough Diamond Rift' partly because Tony Jarratt described cavers as 'rough diamonds' and partly because of abrasive nature of the walls of the rift. A hastily convened meeting of the sub-committee on passage names approved his suggestion. It will, however be referred to as RD Rift or RDR from now on in these pages to avoid confusion for those who use Google to look for references to gemstones.

On the surface, a new spoil heap was started on the west side of the dig and Stuart started building a retaining wall for the heap out of the large amount of rock that had come out of the dig during the day. Tim extended his rude shelter round the shaft with more wriggly tin on the south side and a tarpaulin supported on scaffold poles on the north side. He also installed a weathervane on top of the headframe.

Tony and Clive turned up at 1700 hrs, then Tony had a token squirm into the passage, got slightly stuck, came out again and then spent a short time discussing important matters of philosophy and morality with a large boulder in the Annex chamber, finally managing to bore it to bits.

We packed up and left the site at 1830.

Alice Audsley, Chris Batstone, Chris Harvey (Zot), Stuart Lindsay, Nick Gymer, Tony Audsley

Kibbles: 12

Mixer Loads: 5

1030 hrs; Stuart and Tony surveyed the wreckage of humanity at the Belfry and managed to persuaded Chris Batstone, overhung and suffering from a painful knee, and Nick Gymer, suffering from a badly gashed right hand to come over to the dig.

On the theory that we probably had enough working limbs between us, we decided to go ahead. As a bonus, a fully functional Zot turned up out of the blue. Alice was due to arrive at midday with refreshments, so we were well away.

The intention was to shutter segment 5D (four levels down on the south side of the shaft), and extend this to run into the Annex to support the left hand wall, where all the bag stuffing had been going on yesterday.

Segment 5D was to be shuttered using the 'conventional' steel shuttering, but attached to the right hand side of this was to be wooden shuttering for the left-hand wall of the Annex. This required a considerable degree of bodgery both for the shuttering and the reinforcing.

To start with, Tony went down and fitted the steel shutter in position. It was then obvious that the floor needed lowering some more and so he was joined by Stuart and together they filled 12 kibbles of spoil, which were hauled out variously by Zot and Chris. This included the material stacked under the Annex wall on Saturday. After this, Stuart went up and left Tony to play on his own.

[I am not altogether sure of the details about the surface work from this point on, but from the sounds filtering down the shaft it seemed to consist largely of boiling the kettle then drinking tea. But I may be wrong.]

Underground, two 18mm holes were drilled in the back wall of the Annex to take 4 ft lengths of 16mm re-bar. These were then attached to 12 mm re-bars bent at 112 (ish) degrees which were hooked at the end. These were to join the Annex wall concrete to segment 5D. A cat's cradle of more horizontal and vertical 12 mm re-bars was made inside segment 5D which looked like it might do some good. Four 12 mm holes were drilled in the back wall of the Annex close to the line of the ply shuttering and the back end of the ply was secured by 10mm re-bar pins and wooden wedges, the gaps being sealed with scraps of polystyrene (wonderful stuff).

The shaft end of the ply shuttering was abutted against the steel work and sealed, as ever, with a thin strip of polystyrene. It was held in position by re-bar and wedges jammed down from above, a G-clamp onto the steel work (which later fell off) and I am not quite sure what else, possibly luck, but whatever it was, it didn't move.

Then started a mammoth concrete mixing session. A letter-box slot had been cut in the ply shuttering, but in practice a large proportion of the concrete was fed in via the shuttering for 5D and pushed along to the back of the void with a 4ft length of 25mm plastic water pipe. As the shuttering filled, it had to be fed from both ends, which was quite (actually very) tedious in practice.

The highlight of the day as far as I was concerned was, late in the afternoon, receiving a bucket of concrete with a mug of tea embedded in the top. This was most appreciated. Altogether, five loads were mixed, lowered, trowelled and tamped. This was a long day and finished at about 1900 hrs in the evening to a wonderful mackerel sky in the west.

This account could have done with a few pictures, but I didn't take any - too busy doing stuff.

Note added 7th October: During the afternoon, a hot-air balloon flew over some distance to the east of the dig. We didn't know it at the time but the passengers were Mike Hearne and his family on a birthday trip. Mike photographed the dig on his mobile phone (at 18:47) and he has just sent me the result. So, we did get a photograph after all. Behind the dig can be seen Chris' Volvo and Stuart's van; my Land Rover is parked to the left of the dig but apparently invisible as befits its ex-military status.

Alice Audsley, John Williams (Tangent), Mike Wilson, Stuart Lindsay, Tim Large, Tony Audsley

Ron Wyncoll

Kibbles: 15

It was the day of the B.E.C. [Bristol Exploration Club] Annual General Meeting. Fortunately, this finished in time to allow those of us who were not going to the dinner to have an afternoon session at the dig, starting at about 1500 hrs. In the event, this turned into quite a major session, with Stuart Lindsay and Tangent digging at the bottom and the rest of us providing surface support.

Fifteen kibble loads were sent up, with a high proportion of rock in the spoil. The area at the back of the Annex chamber was lowered by a couple of feet producing about a 45° slope down to the rifts. The rift on the right continues down getting slightly wider, but the bottom portion is solidly choked with mud. However, the upper section continues open for some 10-12 feet. The rift on the left looks more interesting, the entrance is almost caveable and it slopes away downwards into blackness. Two large boulders need removing before it can be approached more closely.

In the late afternoon, Tony went down, admired the rifts, but exclaimed mild horror about the way in which the concrete of the left-hand wall of the chamber had been undermined and so spent quite some time stuffing bags and rocks back into the void to support the fill dangling above.

This fill obviously needed concrete support ASAP, but we had potential labour problems on Sunday; Mike and Tim were not available and Alice was only free in the afternoon. On top of this, Saturday evening was BEC annual dinner, so there was some considerable doubt that we would be able to get together a sober enough team for Sunday to do the concreting. If this were to be the case, then the next digging opportunity was a week away and the fill would have to be supported until then; hence the bag stuffing.

We finished and packed up at 1830 hrs.

Alice Audsley, Tony Audsley

A short visit in the afternoon for Alice to inspect the great works at the bottom of the shaft and for Tony to replace the leaking fuel tap on the winch petrol tank with another, (almost as old but a different design), which hopefully won't leak QUITE so much as the old one.

Watered the sunflowers.

Alice Audsley, Stuart Lindsay, Tim Large, Tony Audsley

Kibbles: 16

During the week the plan to concrete in the roof boulders was changed to one of drilling the right-hand wall to take 22mm pins and using these to support scaffold poles with sections of railway sleeper on top. So as before, we arrived at the dig loaded up to the eyeballs with dig-fix-it kit.

After Tony had taken a few photographs of the annex chamber before work started, Tim and Stuart went below and after removing the timber shuttering from the left-hand wall of the chamber, they began clearing the floor. Then started a hauling session in which 16 kibbles of rock and sludge were taken to the surface. A large mudstone boulder was successfully capped by Stuart and reduced to manageable fragments.

During this morning and mid-day session, Tim and Stuart unearthed two rift like passages low down at the rear of the chamber. These appear quite small but both look like they will get bigger with increasing depth. The one on the left drops about a metre and then appears to head west, the right-hand one trends north-west. It is not impossible that these will merge into one as we dig lower.

The floor of the chamber needs lowering considerably before we can get a better look at these passages, but we need to fix the roof before we start on this so the afternoon session involved Tony fitting 22mm re-bar pins into the right-hand wall and then fixing scaffold bars between these pins and the top of the concrete shoring wall on the left of the chamber. The surface team then sawed a couple of lengths of railway sleeper which were then fitted on top of the scaffs to support the worrying boulder hanging above the the entrance.

The sleeper timbers also support the less worrying but more dangerous blackened boulder hidden behind and above. This was more dangerous because it was more likely to fall, having already slipped, and it held back a lot of 'stuff' above. However, it was less worrying because it was quite difficult to get a good look at it unless you went in to the chamber lying on your back, in which case you got a very good look at it, but that was not the sort of thing that you did more than once. It did raise a bit of prickling at the back of the neck while drilling the wall underneath it but that could have been due to over-active imagination.

The photograph on the left is taken looking into the 'annex chamber' before removing the boulders on the right and excavating the floor.

The photograph on the right shows a closer look at the boulder floor

(Click on either to enlarge).

8432: Detail of the small rifts at the rear of the chamber. the triangular hole on the left descends for about a metre then appears to head west. The rift on the right is open for a couple of metres and heads north west.

8430: Detail of the rift on the right; it is small but beautiful none the less.

8440: Scaff bars and one section of sleeper supporting the entrance boulder (and the stuff behind). OK, the sleeper is upside down but it was hammered into position before I realised this and it doesn't now want to come out. A second length of sleeper has since been fitted to the left.

Alice Audsley, Mike Wilson, Stuart Lindsay, Tim Large, Tony Audsley

Kibbles: 10

Mixer Loads: 2

This was a fantastic day's digging, although frequent and very heavy showers of rain made life a bit difficult on the surface. Tim's rude shelter certainly proved its worth.

We had decided to try to fix the entrance to the rift extension before it all collapsed, so we arrived on site with the whole paraphernalia of the complete cave fix-it kit including:- generator, saws, angle grinders, scaff clips, Hilti drill, 240v SDS drill, crowbars, a sheet of plywood and other items too numerous to mention.

Tim and Stuart went down the shaft in an attempt to expose the left hand wall more completely and at the same time avoid a collapse of the stuff lurking above their heads. They sent up 10 kibbles of spoil, largely rock and cleared the extension down more or less to the level of the base of the shaft. The extension was roughly semi-circular in plan and lacked the expected rift like feature thought to exist buried under the fill on the left. Some rocks fell from above during the excavation but they missed the diggers. Some also fell later while we were on the surface eating our lunch.

After lunch, Tim and Tony measured up for some plywood shuttering to support the fill at the left of the entrance. Tim then went aloft to cut the shuttering board while Tony remained below to drill 20mm holes in the back wall to take re-bars to reinforce the concrete and some 12mm holes for pins to support the shuttering ply. The cut ply was lowered down the shaft, fitted into position and held in place with a combination of short lengths of 10mm re-bar drilled into the rock, wooden wedges and blocks of polystyrene foam, a truly awesome combination of materials.

With the shuttering held firmly in position, two mixer loads were sufficient to fill the void behind. The next stage is to concrete from the top of this new wall across to the right hand wall and seal off the rocks above. Oh Joy!

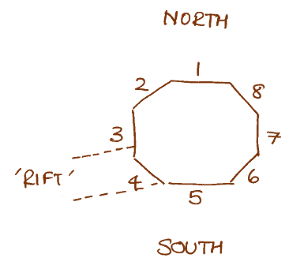

The plan below shows the nature of the extension and the shuttering for the unstable part of the left-hand wall. There are a couple of sizeable blocks in the floor, to the right is a narrow trench in the fill and some degree of undercutting to the right-hand wall can be seen.

Rough plan of the extension.

Tim Large, Tony Audsley

An afternoon session (1400 - 1700), initially with the intention of removing the shuttering from segment 1D. Tony went below and unbolted this, while Tim worked on extending (upwards) and generally strengthening his wriggly tin shelter. Tim also fitted tarpaulins to the north and south sides of the shaft to help keep out the rain.

Tim then went below and probed the rift on the left and DISCOVERED THE LEFT HAND WALL. So we do have a left hand wall and it is within reach and so we can dig the site as planned. All we need to do now is to sort out the crap directly above. There is a largish black boulder towards the back of the rift and this has shifted position since last week. It would be good if we could keep it more or less in position as it is holding quite a lot of stuff up.

Tony then went below and drilled three 20mm holes in the wall under the black boulder and then inserted metre long bars to try to dissuade it from moving further down.

What a great afternoon.

In case you missed it the first time,

WE NOW HAVE A LEFT HAND WALL !!

Mike Wilson, Stuart Lindsay, Tim Large, Tony Audsley

Kibbles: 11

Mixer Loads: 2

Tim and Tony arrived somewhat earlier than the others and came to the conclusion that we were in for a fun day as the rain, although not very heavy was coming at us sideways from the south-west. Tim set about constructing a Tim Large Patent Weather Shield, (in other words a Rude Shelter) which was (a) effective and (b) made the site look like a proper Mendip dig by moderating the air of creeping neatness that it had been acquiring recently. The shelter needs a little bit of modification but it did work very well and was much appreciated.

With the arrival of Stuart and Mike we started digging. Stuart was persuaded to go underground, possibly because he did not realise just how squalid the bottom of the shaft had become. He dug a trench across the west side of the shaft, preparing for the excavation of segments 1D and 5D (ie on the north and south of the shaft. Eleven kibble loads later, he had lowered the floor against the west wall and excavated the hole for segment 1D.

By now it was lunch time so Stuart came up and then prostrated himself by the shaft in a vain effort to persuade the rest of us that he had been working hard.

After lunch Tony went below and Mike, Stuart and Tim mixed two loads of concrete which were duly fed into the shuttering and TAMPED.

A very satisfactory day's work.

Tim Large, Tony Audsley

Les Oxborough visited

Kibbles: 11

Firstly, Tim unbolted and dismantled the two sets of shuttering from segments 8C and 6C. Then we had a look into the extension rift and a joint ponder on what to do about it.

Whatever way we looked at it, the left wall seemed really quite horrible with no solid visible. So, having pulled a few of the bags out that had been stacked in there on 27th June, we thought that it would be a good idea to have a bit of a hauling session to clear out the bottom of the shaft.

Tim stayed below and did the digging and Tony worked (slowly) on the surface tasks. We eventually managed to haul 11 kibble loads. Les turned up mid afternoon to check up on us.

Examination of the rift reveals that the left hand wall is boulders and mud. However, one of the boulders looks large enough to be useful if we can hold it in position. Looking straight up into the roof of the rift reveals quite large blocks with voids between them. Not nice but with any luck it will stay put for a while. The right hand wall is showing signs of undercutting at its base.

So, we need to get a couple of feet lower to get an idea of what is going on with the wall.

Jake Baynes, Stuart Lindsey, Tony Audsley

Stuart and Jake delivered six 8 × 4 ft sheets of ply to the dig to be used for constructing a lean-to weather shelter against the side of the digging hut. Stuart and Jake did all the heaving getting the sheets into the depression and Tony stacked them against the back wall of the hut and then wrapped them in polythene sheeting to protect them from the weather.

5-SEP: The photograph was taken today during a quick visit to finish off the wrapping of the ply-wood (T.A.)

Chris Harvey (Zot), Mike Wilson, Stuart Lindsay, Tim Large, Tony Audsley

Kibbles: 10

Mixer Loads: 4

A long day, (1000-1730); the first time we have tried to complete two segments in a day. Tony went down first and removed the most of the shuttering from segment 7C. All that is except the right side cheek, which defied removal for quite a long time. All the iron work was eventually sent to the surface and then Stuart went down and excavated segments 8C and 6C, ie either side of the segment concreted on Monday. He finished by lunch time having sent up 10 kibbles of spoil.

After lunch Tony went down and set up the shuttering and then followed an uneventful but rather lengthy concreting session. The surface team were adamant that they only sent down three mixer loads worth of concrete. The underground team (me) thought it was more; but then one of the buckets did land rather heavily on my head and jumbled the mechanism within, so I'm probably in no position to argue.

So three it is.

4-SEP - The surface team have recanted - it WAS four mixer loads after all!

Alice Audsley, Mike Wilson, Stuart Lindsay, Tim Large, Tony Audsley

Kibbles: 12

Mixer Loads: 2.5

Tim went below and sent up all the bags that had been stacked at the base of the shaft on Saturday. He then dug out for segment 7C, sending up 12 kibble loads in all. Meanwhile on the surface, Mike was the engineman, Alice was banksperson, Stuart wheel-barrowed, stacked, built retaining walls and Tony faffed.

We broke for lunch, then Tony went below and assembled the shuttering, while the surface team measured and bent re-bar which was carefully lowered then fitted into the slots in the shuttering. Then started the usual round of hauling aggregate, mixing, barrowing, lowering then trowelling into the void and then poddling it. There is probably a correct technical term (†) for vibrating concrete to remove voids but I don't know it, so poddling it has to be. (It's done with a poddling stick).

Two and a half mixer loads were used to fill the void and Stuart used the rest to hold his wall together.

We left at about 1600 hours after a very satisfactory day's digging.

__________

(†)Apparently, the correct term is 'TAMPING'; but I think my word is better.

Alice Audsley, Jeff Price, Stuart Lindsay, Tony Audsley

Kibbles: 7

(Entry number 104 isn't a mistake, I left a tedious engineery log entry out - I enjoyed doing it but it doesn't make a good read).

Alice and Tony arrived early and started clearing at the bottom of the shaft. Finding that it was possible to work the hauling system (slowly) with just the two of us, we eventually hoisted 7 kibble loads to the surface.

Jeff then arrived, having been delayed by problems in Bristol which meant also that he also would have to leave early. Because of this, we decided that it would not be possible to do any concreting this afternoon.

Segments 6, 7 and 8 still require excavating and concreting and the plan had been to do the central segment (No. 7) first and then do both 6 and 8 next weekend. So, to move things on as far as possible, Tony excavated the fill in front of 6, 7 and 8, bagged it and stacked the bags back into the space just created.

Plan A being thwarted, we devised a new wonder plan B. This is to have another session on Monday, when we can quickly whip out the stacked bags and throw in a great dollop of concrete and live happily ever after - well that's the plan anyway.

Alice Audsley, Tony Audsley

Alice and Tony travelled deep into the dark realms far to the east of Frome to see an exhibition of the work of MacDonald Gill, a much underrated artist, designer and architect (d. 1947). Realising that this was not a sufficient excuse for missing digging, we managed to bring back a (hopefully restorable) Honda cement mixer engine. Will try to fix this on Monday. It's always good to have a spare. [Didn't quite fix it on Monday - need to get new gaskets, etc.]

Alice Audsley, Bill Combley (Wormster), Dudley Herbert, Mike Wilson, Tony Audsley

Kibbles: 15

Mixer loads: 2.5

A dry day on the surface but very wet underground. To start with Tony went below and set up the shoring ready for working on segment 5C. i.e. directly opposite 1C or the other side of the rift feature. As the surface was dry and (almost sunny) and underground was wet and 'orrible, no-one else showed a great desire to go underground, so Tony stayed below and sent up 13 kibbles of spoil.

There was then a break for lunch, after which Dudley went below and dug and bagged two loads of spoil. He said it made his soul feel better, which is always a good thing to do.

After that Tony hogged the fun again and went below to set up the shoring for 5C. This was not altogether easy as the fill was very wet, in the mood to misbehave and eager to collapse. So the excavation had to be conducted as rapidly as possible.

Initially, the spoil was bagged and the bags were stacked round the base of the shaft. As the need for haste increased, the spoil was thrown over the digger's shoulder and plastered against the back wall of the shaft.

Eventually, the segment was cleared out, the shuttering was finished and the reinforcing installed. Panic over and we settled down into the well-worn routine of mixing, lowering, trowelling and tamping. Two and a half loads were mixed and most of this was used underground. The remainder was spread round the base of the digging hut to discourage small furry creatures from tunneling in.

Six and a half hours. A tiring day for all concerned. We could have done more because there are something like another 10 loads of spoil to be removed from the bottom of the shaft. But enough is enough. All credit to Bill who did a lot of the surface heavy work despite having broken his collar bone recently in Swildons. (Although it served him right for going to such an awful place).

Alice Audsley, Tony Audsley

Quick afternoon visit to fix the new half section of ladder to the bottom of the existing ladder and to remove the shuttering from segment 1C. Both tasks accomplished despite Mendip mist and squalid, wet conditions at the bottom of the shaft. The shaft shelter fitted in July provided a welcome degree of protection on the surface.

Tony Audsley

A pleasant afternoon spent finishing off a short, 5 ft (or 1.524 metres if you must) length of ladder. It seemed a good idea to use 12mm rebar for the rungs because the dig had some to spare and it was FREE. However 12 mm rebar doesn't fit into half inch holes, not even when they are drilled out to 13mm. But if you hammer something hard enough, eventually it will go in, so that's OK. Having persuaded all the rungs to fit in a bit of weld was splashed on to make sure they stayed in.

8293: |

8303: |

8304: |

Photograph 8293. Shows the sides being drilled, supported on a cunning slideway running through the machine vice. |

Photograph 8303 shows the assembled parts of the ladder clamped in position ready for welding |

Photograph 8304 shows the completed ladder basking cheerfully in the afternoon sun, blissfully unaware that it is soon to descend into the squalor at the bottom of the shaft. |

Alice Audsley, Dudley Herbert, Mike Wilson, Tony Audsley

Kibbles: 4

Mixer loads: 3

Tony went below to have a final clear-out of segment 1C and sent up 4 loads of mud and small stones. Alice acted as banksperson, Mike as engineman and Dudley took the part of spoil-heap monitor. A thoroughly good time was had by all.

We had a break for lunch and a natter in the sunshine, then Tony went below again, fitted the right-hand side cheek to the frame then installed various bits of rebar cunningly cut and bent by the surface team.

During the afternoon, Alice, Dudley and Mike shovelled, carried, mixed and lowered and Tony sat down below and trowelled the concrete into the shuttering. A slow, steady and uneventful afternoon's work.

Next weekend - same again

Tony Audsley

Start of a ladder making session to produce a 5 ft intermediate section of fixed ladder. When I made the last batch of ladder in October 2008, I had prepared a ten foot length of the flat steel strip to act as a jig for making future sections. This was drilled with small holes at the correct centres for the the rungs and the fixing bolts.

All that was necessary this time was to find the jig (ha-ha!) then to pop through it with a small diameter punch to mark out a new strip. Having marked the centres, the strip was then drilled with ¼ inch pilot holes. At this point rain stopped play, it's a start, anyway.

I won't apologise for the 'old fashioned' imperial units. The steel stockist that I use supplies 40 × 8mm strip in 20ft lengths, even though the invoice calls it 6.1 metres. These I cut in half to give 120 inch lengths of steel strip which divide nicely with 12 rungs spaced at 10 inch intervals. 10 inch rung spacing is a comfortable step size and was traditional for Mendip ladders anyway.

Alice Audsley, Dudley Herbert, Jeff Price, Mike Wilson, Paul Brock, Tony Audsley

Kibbles: 13

Excavation for segment 1C. The plan was to lower the floor in front of segment 1B and then excavate under 1B to reach the wall behind (to the north). Paul, Tony and Jeff took turns underground. Fortunately, Paul did most of the hard work. Dudley Herbert came over for a look-see then ended up emptying bags on the spoilheap. For some strange reason he seemed to enjoy this.

We, (or rather Paul), got the floor lowered satisfactorily, with a decent pit in front of 1C, then we started excavating under the concrete to get to the rock wall behind. We had expected to expose solid rock a short distance in at the back of the excavation, but found instead that the wall seems to have receded to the north, away from the line of the shaft. So it was not practicable to pin 1C into the rock as we had intended. This was a bit of a problem as I had prepared a special set of shuttering based on the assumption that the concrete would be pinned to the wall behind. However, the cave makes the rules, so who are we to argue with it?

So with our best laid plans having ganged ever-so-slightly a-gley, we uttered a string of magic words, put in some temporary shoring and packed up for the day, with the intention of having a bit of a think and then returning revitalised to do the shuttering and concreting on Monday.

Alice Audsley, Tony Audsley

Alice and Tony paid a brief visit in the afternoon to take some photographs.

8259:The shuttering for segment 7B |

8261: The shuttering frame for segment 7B |

8262: The way on, but it's blocked for now |

8266: The shaft bottom |

Photograph 8259 shows the shuttering in place on segment 7B. It also reveals evidence that the mix we were using was a bit on the wet side. It's not all like that, but I squirted some water in to dampen down a rather dry mix and overdid it just a bit.

Photograph 8261 shows more or less the whole shuttering frame, the two upright members held in place by a cross member bolted to the segment above. An old bit of wetsuit can be (just) be seen helping to tension the left hand upright. The modified 'letter box' shutter allows the lower segment (7B) to be filled to the top.

Photograph 8262 shows the so-called 'way on'. It's blocked for now and is a useful place to store tools and stuff. The two drain-water pipes have been poked into the bottom of the rift, so with any luck it is digging itself while we carry on with the cementing.

Photograph 8266 is looking straight down the shaft. The shuttering frame is holding up segment 7B (East). Segment One (North) is at the bottom of the photograph with the spade leaning against it. (The blurry blue thing in the bottom right hand corner is my leg).

Alice Audsley, Jeff Price, Mike Wilson, Tony Audsley

Kibbles: 5

Mixer loads: 2.05

First thing, Alice and Tony finished off the work on the shelter by fixing down the cladding with good old MVF21434 - SCREW, ROOF & WASHER 14G x 32 TO WOOD, (that's what Mole Valley Farmers call them and they should know, they sell them.

Tony then went down below and removed the shuttering from 6B and set it up on 7B, the last segment on this ring. Meanwhile, Jeff and Mike arrived, so Jeff then took over and cleared the base of the shaft and dug out segment 7B, sending up 5 kibble loads with Mike as Engine Man.

We had a quick break for consumption of hot dogs, then Jeff had to leave, so Mike and Alice started bending three lengths of rebar as required. Unfortunately, the jig slipped when Mike was bending a bar, trapping his finger between the jig and a scaffold tube. This resulted in a string of 'they words' and a very painful looking bluish purple finger, possibly due to lose its nail.

Despite this, Mike and Alice carried, mixed, poured and lowered concrete while Tony sat at the bottom trowelling and ramming the stuff. Using the new 'letter-box' technique the segment was filled right to the top with two mixer loads of concrete.

To be strictly truthful, two mixer loads did not completely fill the segment, so the surface duo personfully mixed about half a bucketful by hand and that was exactly the right amount.

Good session. Even Mike thought so, despite his throbbing finger.

Jeff Price, Tony Audsley

As we drove over to the dig, we saw a buzzard perched on the headframe eyeing up a pheasant on the ground below. The buzzard flew off and the pheasant waddled away to live for another day.

Having frightened all the wildlife away, we continued working on the scaffolding for the shelter. It's much easier with two. We laid two planks over the scaffolding framework and then laid cladding taken from an old up-and-over garage door on top of the planks. These planks were fixed to the scaffolding using 'U' bolts bent out of good old 8mm studding.

We ran out of time before we could secure the metal cladding to the planking. We just popped some timber on top to stop it all blowing away before tomorrow morning, when we'll fix it properly.

Tony Audsley

Set up a rough scaffolding framework by the shaft with the intention that it should form the support for a shelter over the shaft working area. This is an attempt to produce a better environment for the surface workers, which is probably more than they deserve. The attempt may be doomed to failure anyway as the rain tends to arrive more or less horizontally. We shall see.

Alice Audsley, Mike Wilson, Stuart Lindsay, Tim Large, Tony Audsley

Kibbles: 5

Mixer Loads: 3

Tim and Stuart arrived before the rest of us and they started work on building a spoil-heap retaining wall to the south of the engine house/digging hut. (When we have built up a sufficiently high platform of spoil behind this wall, we'll build a lean-to against the engine house to act as a wet-weather shelter for the surface workers). Stuart then had to leave to meet up with Trevor Hughes and work on another from their vast portfolio of digging sites.

Tony then went below and drilled a series of 45 degree holes in the bottom of segment 6A, then chiselled out a wedge of concrete. This was to create a space so that the segment below could be completely filled with concrete. This would eliminate the need for pointing in the gap afterwards. He then set up the shuttering frame for segment 6B. There was an overwhelming lack of enthusiasm on the part of the others when offered the chance to leave the sunshine and get into the slime and do some digging, so Tony stayed below and sent up 5 kibble loads of spoil.

Mike spent some time furdling with the mixer engine and got it to run rather more sweetly than it did last week. Unfortunately Mike then had to leave after the first mixer load, but Tim and Alice made a valiant effort and kept the concrete flowing freely for the next two loads.

Having cut a channel in the base of the segment above, it was possible to fill 6B completely to the top using the new 'letter box' top shutter plate. Three mixer loads were required and we finished at 18:30.

Dave King, Jeff Price, Tim Large, Tony Audsley, Alice Audsley

I am rather hesitant about writing this up as it was not a very successful day, but in the interests of truth, here goes.

Dave King (ATLAS and MNRC) came over clutching a doctor's note to excuse him from digging, which was not really necessary as very little actually got done. Dave did manage to get the sump drainage system working again after it had stopped for some reason. Tony went below and removed the shuttering from segment 8B and then retired to the digging hut in TORRENTIAL rain. There was a proposal that we should adjourn to Hunters' for a planning session and the motion was carried unanimously and enthusiastically.

Meanwhile, the rain abated and Alice, as prearranged, turned up at the dig, worked out where we would be and waited in vain for an hour for our return. Mobile phones are wonderful things, but they need to be turned on.

That's it. Must try harder next time.

Jeff Price, John Williams (Tangent), Tony Audsley

Jeff and Tony removed the shuttering from segment 5B, then Jeff fitted a short section of electron ladder at the bottom of the shaft to help aged diggers get out of the hole.

Tony then tried probing for the left-hand wall of 'The Way On' (TWO). Working at full stretch, managed to clear a small section that looked fairly promising. However, having drilled a couple of holes with the intention of inserting rebar supports, it turned out to be a large boulder.

Tangent came down and had a furdle into TWO. He was impressed by the open space and waxed lyrical about the right-hand wall, but was singularly unimpressed by the left.

At the moment, it does not seem possible to get at the solid left hand wall of TWO, assuming of course that it exists at all. We need to excavate one more level, install ring "C" and try again. Rather disappointing, it is going take longer than we had hoped, but we'll get there.

Jeff Price, Chris Batstone, Tony Audsley

Kibbles: 5

Mixer Loads: 5

Jeff started excavating for segment 8B and sent up 4 kibbles of spoil including some appreciable rocks. At the bottom of the excavation, clean voids and blackened rocks started to appear.

After a break for tea, Tony went down,sent up another kibble of spoil then set up the shuttering and reinforcing. After yet another tea break, Cecil B. de Batstone went down to test out his new lightweight video camera (we await results of this).

Finally Jeff and Chris, both suffering from the after effects of heavy colds, variously ferried aggregate, coughed, mixed, spluttered, ferried more aggregate, wheezed and lowered buckets of concrete to Tony who sat on a plank bench underground and leisurely troweled it into the void. They even sent down a cup of tea in one of the buckets of concrete; it was much appreciated.

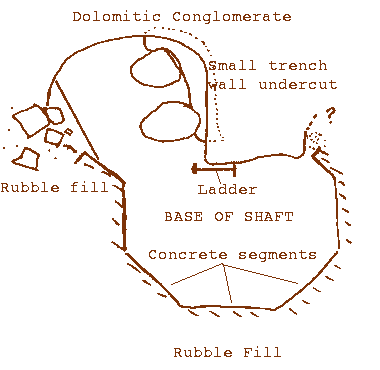

Footnote on segment numbering: I have been referring to the octagonal segments of concrete quite happily by numbers without making much attempt to explain this so here is a belated explanation.

The segments are numbered ANTICLOCKWISE from #1 on the north side of the rift as shown in the following neatly crafted diagram:-

Segments have suffix A, B, ... where A refers to the topmost ring, B the next and so on.

Number 1 was the first segment cast because I thought it was the closest to the rock wall (it wasn't; 2, 3 and 4 were). The segments are numbered anticlockwise because there was a large boulder under 6 and 7 and I thought that it was supporting the shaft and ought only to be removed after the shaft had some other support (this turned out to be a mistake as well, but 20/20 hindsight is a wonderful thing; would that we were all born with it).

That's all.

Alice Audsley, Jeff Price, Mike Wilson, Stuart Lindsay, Tony Audsley

Kibbles: 7

Mixer Loads: 2

Driving over to the dig at 1000 in the morning saw a pair of hares disporting near the dig, which was a good start to the day.

Some time later, having sorted ourselves out, Stuart went down and started work on excavating section 5B, sending up 7 kibbles of spoil. After lunch, Tony went down and installed the shuttering and reinforcing, then made himself comfortable on a seat of planking and fed in concrete prepared by the surface team. Two mixer loads in total.

The bottom of the fixed ladder is now at head-height and it is getting difficult to reach it. Need to make some more.

Alice Audsley, Tony Audsley

Tony went down the shaft and removed the shuttering from position 1B. There is quite a void between 1B and its neighbour to the right (8B), so perhaps we ought to concrete 8B this Saturday. Took some of the shuttering steelwork back home for cleaning and as a pattern for drilling holes in the half-made second shutter frame.

Tony Audsley

Took the old shutter/shield to the Belfry and spent a pleasant time cutting up a sheet of steel with an angle grinder. This effectively disturbed the slumbers of the festering Belfryites who were sunbathing on the lawn nearby.

Alice Audsley, Duncan Butler, Ian Gregory (Slug), Jeff Price, Les Oxborough, Stuart Lindsay, Tim Large, Tony Audsley

Kibbles: 8

Mixer Loads: 4

Tim and Stuart started digging out under concrete segment #1. They bagged their spoil and stacked it in the riftlette as a temporary measure to prevent the left-hand wall collapsing. Having filled this they sent a few bags up to the surface.

I had hoped that the rock wall of the main rift would be trending to the south (ie into the main rift), but instead, if anything the main rift appears to be widening. The plan for this segment had been to angle the shoring towards the rock wall to produce a tapering concrete plug. But the wall did not agree with this plan so it had to be abandoned. By the rules of the game, the cave always has the last word.

Tony went underground, cleared out the void a little bit then installed the MkII version of the shuttering. This simply bolts to the concrete above and is altogether slimmer, simpler and more beautiful. Tony drilled the wall and inserted pins then created a rat's nest of reinforcing. The surface team then started a mammoth mixing and lowering session. Initially the mixer engine started to have tantrums for some reason best known to itself, but eventually it started to behave. Down below the concrete was poured and prodded and occasional holes between the shuttering and the rock were blocked off with bits of polystyrene (great stuff).

By the end of the day, an unknown number of bags had been stuffed into the way on, 8 Kibble loads had been hauled out and 4 loads of concrete poured into segment 1B ( '1' being the north most position and 'B' implying 1 level down). There remains a small void of two to three centimetres between the segments which still needs filling, but the existing concrete needs to harden somewhat before this can be done.

Tea, cakes and buns were enjoyed by all during the day, as befits such a civilised dig.

Lots of words, no pictures - too busy to take any - sorry.

Tony Audsley

Quite a long day working at home (0900-1800). Continuing with mods to the old shuttering and making up a second 'light weight' set so that if necessary we can cope with two segments at a time. Nothing exciting just slow drudgery.

Tony Audsley

Collected some rebar and took it to the dig then collected some angle iron from the dig and took it home.

Spent the rest of the day working on modifications to the shuttering so that we can use it for concreting the next ring and the entrance to the riftlette.

Still a bit more to do.

Alice Audsley, Tony Audsley

A quick morning trip to take some photographs and collect the shuttering frame for refurbishment, fettling and generally fiddling with.

Shaft bottom with pit below the ladder |

Left hand wall supported by Acrow |

Looking into the Riftlette |

Looking closer into the Riftlette |

Mike Wilson, Tony Audsley

A quick morning visit for Mike to attend to the petrol leaks on the winch and to try to fix the rather erratic slow-running.

Meanwhile, Tony dredged the bottom of the "wishing well" sump and lowered the level of the blue drainage pipes, then fixed them in position.

Later we both went below and examined the left wall of the riftlette then had a think.

Unfortunately, probing with a bar revealed that the solid rock left-hand wall is too far away for us to get away with pretend shoring. It needs serious attention to the entrance area and the roof, so we will have to lower the main shaft floor and deal with it from a lower level. We can bag the spoil and stack it in the riftlette for the time being to support the left-hand side.

Remembering Golden Rule No. 1; "A solid roof means happy diggers"; it's back to the concreting we go.

Oh well, the digging was fun while it lasted, but open passage is always the ruination of a good dig, so it's good to have a valid excuse to fill it back in.

Alice Audsley, Chris Batstone, Ian Gregory (Slug), Jeff Price, Mike Wilson, Stuart Lindsay, Tim Large, Tony Audsley

Babs Williams, Liz Jeanmaire, Mike Wheadon

Kibbles: 16

What a lot of people. What a fantastic day. What a great digging session. Pity about the horse-flies; but one can't have everything.

We dug a trench in the floor of the west side of the shaft going down about a metre and a half, exposing a solid rock wall (dol cong) on the west side of the excavation and we got better access to the continuation of the rift. The digging conditions in the trench could best be described as slightly squalid. This was partly due to Jeff's love affair with the in-shaft washing system, but also because there was a very heavy drip in the entrance to the rift extension.

So what's all the fuss about the rift extension? Well, it is important because it is where we are going to have to dig. It will be easier to shore this rift than the full width of the main rift directly below the concrete shaft. So it's good to have it but there is still a long way to go yet.

So what do we have? First the good news; a solid right hand wall of dolomitic conglomerate, beautifully sculpted and a joy to behold. Now the not-so-good news, the left hand wall is a tottering pile of grot and this will need disciplining PDQ before it decides to collapse. However, the space between these walls is pure delight. It has a degree of openness, the area has obviously taken water over a long period and the fill is largely blackened, angular rock.

Jeff was posted into the hole and wormed his way further in to look down the drop at the end. This was choked about a couple of metres down with clean washed rocks. Getting Jeff back out of the hole was really quite difficult, but as he would have taken quite a long time to rot down if left in there - out he had to come.

By the end of the day, we had removed 16 Kibbles of spoil, had a lot of fun and dug ourselves into a state where we urgently need some more concrete. So it goes on.

A valid excuse for missing a weekend's digging. An excellent dinner attended by 92 Grampian members, which included some Mendip Folk, viz:- Alice Audsley, Anita McNab, Angie Glanvill, John Williams (Tangent), Kirsty Mills, Martin Mills (Milch), Pete Glanvill, Pete McNab (Snab), Tony Audsley. Good food, good company, good singing & good dancing; all helped down with a modest quantity of "Great Northern Brain Wrecker".

Any beer with a cave bear's skull on the label has to be worth drinking.

There were five of us staying with Annie and Roger in Uphall and so we seven shared a taxi to and from the dinner. The taxi ride back from the dinner was enlivened by our driver having to swerve violently to avoid a head-on with another driver travelling rather fast the wrong way along our lane of the dual carriageway.

FOOTNOTE: Unfortunately, the inevitable happened and soon afterwards there was a head-on collision which killed the drivers of both vehicles. There were no passengers in either one. (Report in Edinburgh Evening News, 20th June 2011).

Jeff Price, Tony Audsley

Kibbles: 3

A pleasant afternoon and also the first session of genuine digging!!!! Jeff went on down and started digging a hole in virgin spoil at the side of the shaft nearest the rock wall and the "exciting rift". Three kibble-loads later he had a respectable hole and had created a void under the concrete foundation.

There is an open rift, floored with blackened stones. The left wall visible in photograph (3) is a Mudstone boulder and the right wall is solid dolomitic conglomerate. As the Mudstone boulder is pinned to the concrete with a couple of lengths of rebar, it will probably have to stay where it is and we will work down underneath it.

So far, it all looks very good.

Jeff Price, Pete Rose, Tony Audsley, Tony Setterington, Trevor Knief

An afternoon trip for Jeff and Tony to remove the shuttering and tidy up at the bottom of the shaft and for the others to do a tour of inspection. At least, I guess that was what they intended, but they were pressed into hauling the steel-work and general debris out of the shaft.

Alice Audsley, Tony Audsley

Quick visit in the afternoon to tidy up and take some photographs at the bottom of the shaft. The photograph on the left shows the three part steel shuttering held in position with wooden wedges, while on the right of this photograph there is a bodged plywood shutter held in position with a second prop. All gaps are stuffed with bits of polystyrene foam - where would we be without it?

The second photograph is taken from some 3 metres up the shaft and shows the three steel straps and bottle jacks, the cable guide (bottom right), the shutter frame supported by a ratshit winch, the blue drainage pipes and the yellow hose pipe for washing the rock walls before concreting. All very homely.

Alice Audsley, Chris Batstone, Jeff Price, John Williams (Tangent), Stuart Lindsay, Tony Audsley

Kibbles: 5

Mixer Loads: 6

The space remaining for the last two sectors was, in fact, equivalent to about 1.5 sector's worth, so we decided to do them both at the same time. This also made it easier to place the digging shield to avoid the third shaft strap and bottle jack. So, the shield was positioned slightly to the right, leaving a small space to its left and a rather larger space to its right.

CB went down and went twelve rounds with the boulder before finally beating it into submission. He then sent out 5 (very) full kibbles of stone and mud.

After a break for lunch, TA went down and fitted the shuttering. The space to the left of the shield was plugged with a strip of polystyrene and the space to the right with a cunningly crafted sheet of ply-wood, which was held in position by a second acrow prop. These two crossed props necessitated a rather contorted working posture for the rest of the procedure.

TA fitted the reinforcing, then started filling the void with concrete,supplied by the surface team, who variously shovelled, drank coffee, mixed, poured, drank tea, carried and lowered the full buckets of concrete over and over again, until the sixth mixer load finally completed the job.